2020

PopMount

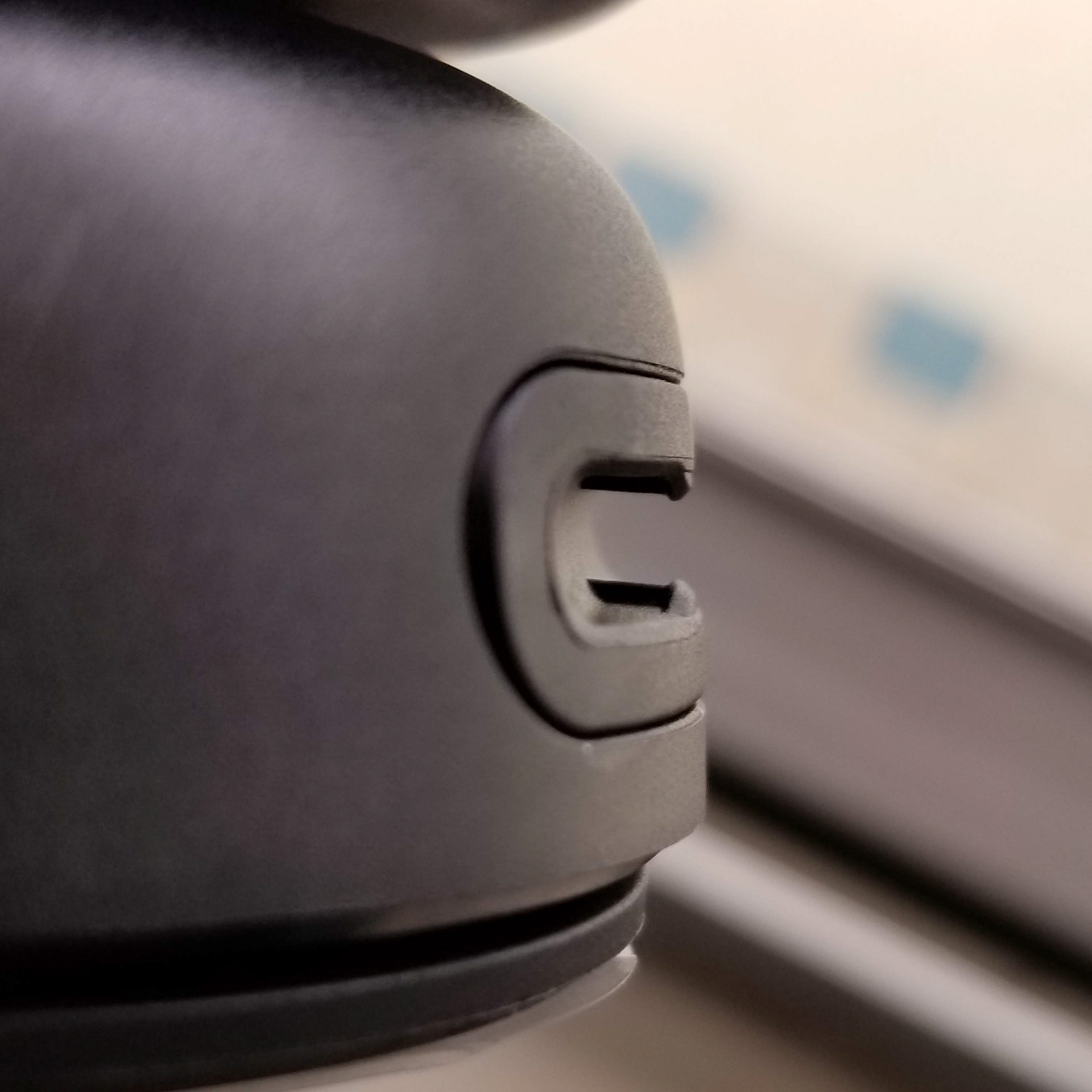

The Popsockets PopMount™ is a dedicated PopGrip utility mount with a unique twist, rotate, and position-into-place functionality. The signature U-shape mount head holds the PopGrip in place while four articulating joints and a heavy-duty suction cup base work to suspend the weight of today's heaviest mobile devices.

....

Process

....

Brief

Popsocket's PopGrip™ has exploded in popularity and recognition for its small but handy cell phone grip design. Clever hand grip finds itself in new and familiar places that reveal unique scenarios in which helpful pairing accessories are needed. Productivity and commuting focus on directing the function, while aesthetics reflect a playful but meaningful identity in mobile utility.

....

Research

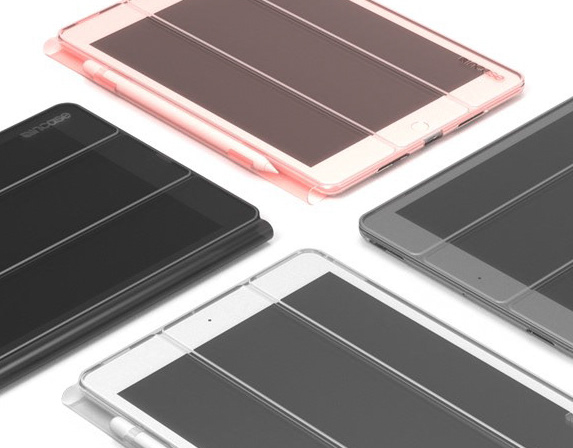

Existing Marketplace // The current landscape for mobile mounting solutions are saturated with generic forms that lackluster memorable brand identity and complementary function for hero products.

Innovative Solutions // Inspiration from devices outside the existing landscape detail several design aspects which resonate with Popsocket's brand language.

....

Initial Concept

Inspiration // Logitech's ZeroTouch™ dash mount hardware.

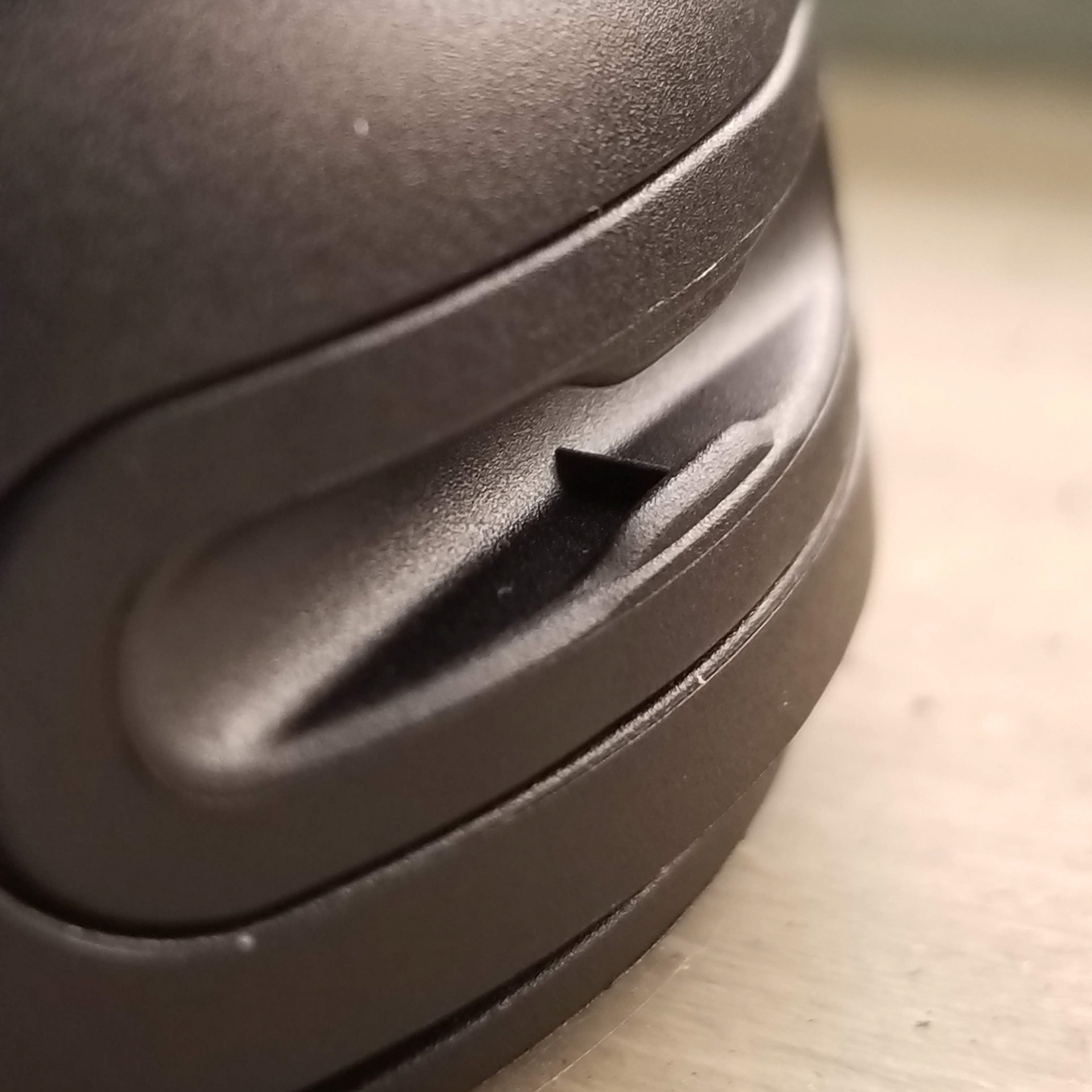

The friction hinge and circular top profile view reflect Popsocket's design language and foster the ideal functionality for a unique PopGrip mounting experience.

....

Direction

The concept originates from PopGrip's concentric nesting attributes found within the thermoplastic polyurethane (TPU) accordion part.

The nesting PopGrip™ rings combined with the vent mount echo the joyful functionality and circular identity seen in the Popsocket's brand.

....

Extension

Collapsed

Inverted

Mock-Up

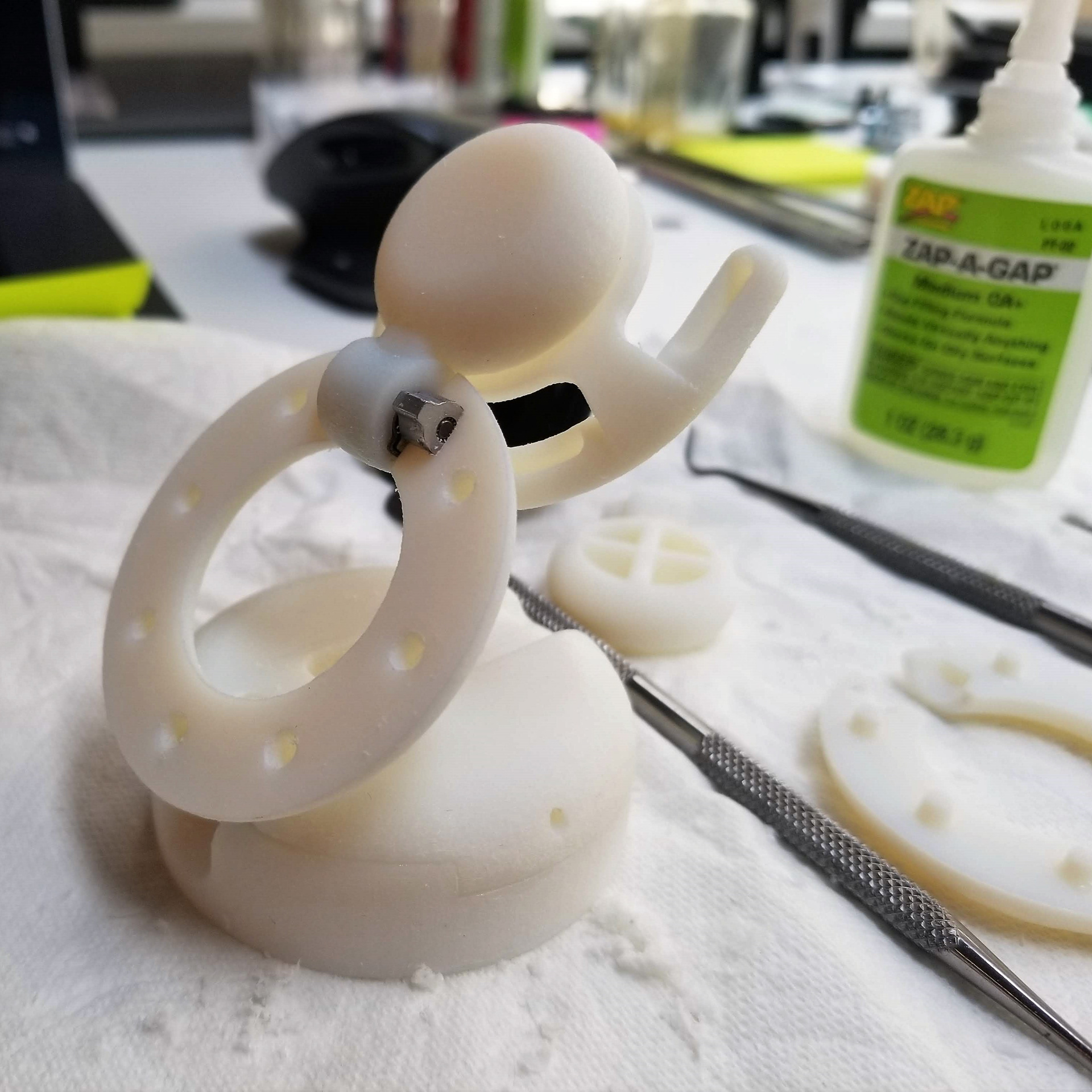

A rough CAD model of the initial design direction was created within Solidworks to validate functionality and user experience.

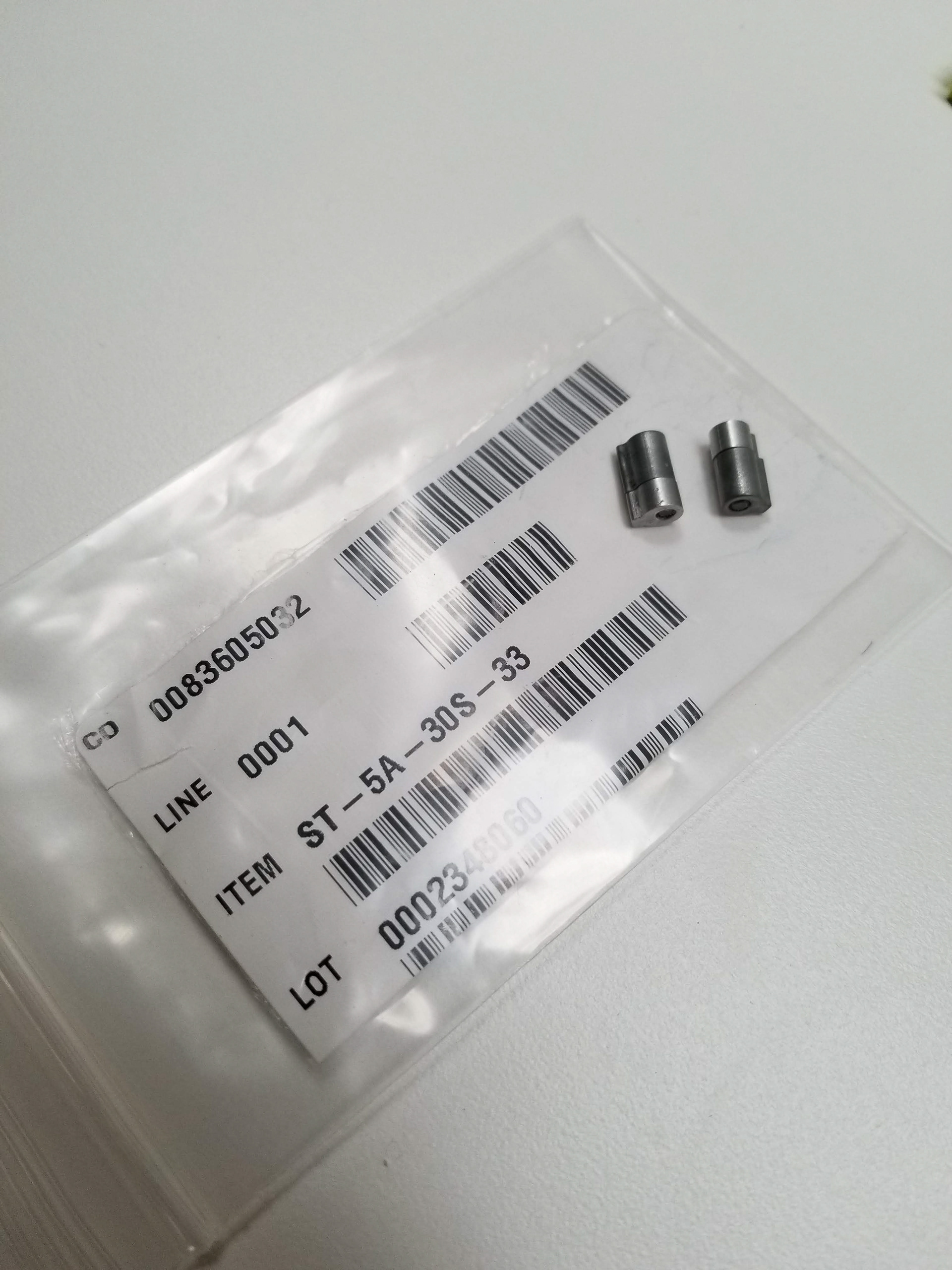

This first mock-up was scaled to accommodate friction hinge hardware scavenged out of the Logitech's ZeroTouch™ suction mount.

....

Concept Refinement

After testing the first mock-up, the second round of sketches highlighted key feature elements to refine.

Cable Management // Articulation Clearances // Mechanical Functionality // Aesthetics Details

....

Movement

An articulation study validated the variety of mounting positions required for identifying clearances and tolerances.

....

Mechanical Anatomy

Rapid 3D CAD modeling tested off-the-shelf hardware and validated the mechanical engineering direction.

....

Validation

Several prototypes concluded the final design direction and proof-of-concept required to proceed with overseas manufacturers to the tooling phase.

....

....

....

....